Kanban Game at the Lego Pub

Here's a neat little kanban game with lego pieces and cups. It's simple, but effective. I haven't been able to find any rules or information online apart from this video, but after watching it a few times, you could easily run this yourself.

There are four stations, with four operators. This video shows an expert crew, following the rules of kanban. ie. Pull production. Obviously, they've played before. When you first run the game, you should be running in batch mode, making tons of inventory, with no regard to whether anyone needs it.

(Unfortunately, the video has been deleted because it's no longer on YouTube. I'll leave the content here, so we don't lose some of the analysis and commentary).

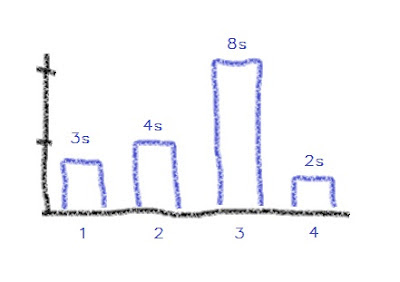

I did some basic analysis of the game and determined approximate times for each station:

There are four stations, with four operators. This video shows an expert crew, following the rules of kanban. ie. Pull production. Obviously, they've played before. When you first run the game, you should be running in batch mode, making tons of inventory, with no regard to whether anyone needs it.

- First station - Put blue lego block in cup and pass to next station.

- Second station - Put green lego block in cup, install lid and pass to next station.

- Third station - Colour sticker with marker, peel off and stick to bottom of cup. Pass to next station.

- Last station - Inspect and pass to customer.

Simple. I'm not sure what the customer is going to do with these shot glasses of lego, but we can assume they are making what the customer wants. Perhaps they're making drinks at a beach resort for lego minifigs?

Take a look at the video, then scroll down for my commentary.

(Unfortunately, the video has been deleted because it's no longer on YouTube. I'll leave the content here, so we don't lose some of the analysis and commentary).

I did some basic analysis of the game and determined approximate times for each station:

|

| 4 Stations - Unbalanced Work |

It's clear from the time study that this is not a perfect process. You could easily combined work to make it more efficient. But we won't, at least not when running the first phase of this game.

Unbalanced flow is the key to creating a good lean simulation. To demonstrate the power of pull production, you need a bottle neck process, like the labeling station above. During the first run, tell your people to go as fast as possible; that they'll be individually rewarded for maximum production. Spread them far apart and use people to be "forklifts" between stations.

Invariably tons of work in process will build up between station 2 and 3. You will even get material between station 1 and 2.

Teach the kanban rules and run the simulation again. You can see from the video that the operators only build when the station ahead of them takes a part. One piece of WIP between stations and there's no more build-up and no waste of inventory. The overall lead time decreases and the unbalanced work becomes visible. Time to fix the problems and combine stations.

This is a great little simulation, perfect for demonstrating pull systems.

Has anyone used this game for teaching kanban? How about different variations? Different colours of lego?

This looks great. Nice and simple. Would be good to build in variability, and a customer request at regular intervals. for eg. Red Blue, Blue Blue, Red Red, Red Black. That gives lots of chance for inventory to build up, and chance to miss customer deadlines. One could make it more complex by having a very fussy customer, who rejects items which aren't up to standard. This would force the supplier to talk with the customer and find out what they need. Thank you for sharing the video and your thoughts. It has got me thinking...

ReplyDelete